Certified Collision Shop Manger

Mentor, Duane Hamilton

Duane is one of two managers at a certified collision shop that does body repair work for a group of luxury automobile dealerships. Auto body collision repair is a well paying skilled trade that has seen many changes because of the introduction of new metals that include stronger yet lighter steels, aluminum and various other lighter materials. These new metals and materials require today’s auto body technicians to be better trained in how to weld and fit parts made from these new materials as well as how to apply the new paints, rivets and adhesives now used by automobile manufacturers. These new metals and materials also require a larger investment in tools and equipment by the dealership to be able to get certified by the manufacturer. In order to maintain a shop’s certification with the automobile manufacturer, technicians are required to undergo ongoing training and testing to update their skills because today materials and production processes are constantly changing.

Duane learned auto body painting and repair by working in shops and getting hands on experience. But there are a number of vocational training schools that teach collision repair in high school and there are more intensive programs run by vocational schools that you can attend after you graduate. In his article, Duane talks about apprenticeship programs offered in his shop as well as training programs offered by technical schools and what you need to do to establish yourself in this trade. His article will be of interest to anyone with mechanical ability considering this well paying trade as well as those of you interested in learning more about how the introduction of new metals, materials and paints has changed the way auto body and collision repair is now done.

Overview

When I was growing up I was interested in learning how things worked and would take apart and fix everything from broken appliances to bicycles. My mother was involved in crafts and when I was a kid she always had projects going on in the house. These projects gave me the chance to learn to draw and paint, something that helped me when I later started painting cars. As I got older, I started working on automobiles and learned to repair them. This kind of experience as a kid gave me an interest in automobiles and I signed up for auto mechanic classes my Junior and Senior year of high school given at Tulsa Vo Tech. But when I got out of school I didn’t immediately go into auto collision repair. I thought that I might want to work with computers and took classes for three months before I decided that was not the kind of work that interested me. Because I was not sure at that point in my life exactly what I wanted to do for a career, I went to work with my father at Saint Francis Hospital helping him in the laundry and linen department. But after a year I decided that I wanted to try auto body painting. I thought I had a talent for painting from doing projects with my mother when I was a kid and also liked working on automobiles. So it seemed like a good fit for me. I went to the yellow pages and tore out the listings for all the auto body repair shops in Tulsa and started calling on everyone of them asking for a job. The last place I went didn’t hire me to work in the shop at first. Instead the owner asked me to come and work with him that weekend cleaning up the landscape and outside of his building. I showed up on time, worked hard and he offered me a job in the shop detailing cars and other odd jobs. I worked quickly to finish what I was assigned each day so I could go back and observe the painters after I was finished. I also went to the library and got books on auto body repair and painting as well magazines that showed how to do custom painting. A painter took me under his wing and I was soon able to paint cars first under supervision and then on my own. I proved to myself that I had talent and could become a good auto painter. But my father had purchase a janitorial company and I decided to quit and go to work with him. We did well for two and half years until the oil market went bust in 1984 and we lost one of our largest clients. I then had to look for something else to do and went back to painting cars. I found a shop that repaired and renovated cars and talked to the owner. He was not sure about hiring a new painter. So I told him that I would work for free for the first week so he could see how well I did and I could decide if his shop was a good fit for me. I ended up working there for five and a half years.

During that time, the local Cadillac dealership wanted to start fresh in their body shop rather than try and solve some of the problems with the present personnel. The Cadillac dealer made a deal with the owner of the restoration shop where I was working to come in and take over the entire operation. My boss agreed and sold his business and brought me and some of the other technicians with him. I worked there for another five years as a painter and then worked at other shops where I was a painter but also learned to do estimates. My boss at the Cadillac dealer asked me to come back in 2006. We were fortunate that the dealership was sold right after I returned and the new owner, Don Thornton, wanted the body shop to be the best and was willing to invest in new equipment and training for the technicians. He also purchased several other luxury auto dealerships and made our shop the one that handled auto body painting and repair for all his dealerships. These now include Cadillac, Lexus, Audi, Jaguar, Land Rover and most recently Volkswagen. I gradually moved out of the shop and now have a management role rather than being a painter and technician although I do get back in the shop if people are sick or we are under pressure to finish a car. We have worked hard to get our technicians trained and certified by the factory and our owner has made the investment in the equipment necessary so that our shop is now certified by all these different auto manufacturers.

One of the main things you do as a manager of a collision shop is deal with insurance companies who have to settle claims. This can require a lot of paperwork trying to explain to an insurance adjuster how some repairs must be made. For example, you sometimes have to order the aftermarket parts the insurance company would prefer you use to save money and then bring them into the shop and show them why these parts won’t meet the factory specifications or fit properly. This can result in delays getting the customer’s car repaired, which doesn’t make anyone happy. Although we try to accommodate the insurance company, we occasionally don’t agree with how the insurance company wants the repair to be done and have to explain to the customer how we would like to do it and ask if the customer would want to pay the difference. Our reputation is important and we never will do a repair that we feel is not going to produce a result that is up to our shop’s standards.

How New Materials Have Changed Collision Repair

The trend in the automobile business has been to build cars with lighter yet higher strength steels and more recently aluminum. This has changed the way that cars can be repaired because these new materials cannot take the same amount of heat as the older steels without losing strength and compromising safety. This heat issue makes it more difficult to fix metal damage and forces you to replace rather than repair many damaged panels like we had in the past. Likewise these new kinds of steels as well as aluminum require much more expensive welding equipment and tools used to do all types of auto body repairs. The manufactures also have strict guidelines on how they want these repairs to be made. Their certification standards require that we go to the manufacturer’s training classes where we are tested in things like welding. Welding is an important skill and auto body welding is much different that pipe welding with much closer tolerances. During this training, our welds are visually examined as well as x-rayed.

Besides new metals, there are also new paint materials. While these give the car a better finish, they have to be applied in clean, dust free paint booths. There are also manufacture’s guideline on how these paints are applied that must be followed. We also have digital systems to blend the paint so that it is as close to an exact color match as possible. Rather than just trying to match paint colors visually with color chips, we also have digital scanners that gives us paint formulas that we can use to help us blend our paints to give us a more exact color match.

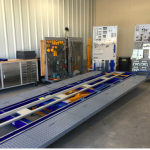

Here are some pictures of our shop including a paint booth, a machine used to repair structural damage to a car’s frame as well as shot of a trunk and panel on the back of a Cadillac CTS that was in the process of having rear end and rear side panel damage repaired. Note how clean we keep the entire shop and the cars we are working on and how the paint booth is sealed so that it is free of any dust.

How to prepare for Career as an Auto Body Technician

- While you are in high school it is important that you take basic math and geometry. You will use it to prepare paint formulas and to properly fit body parts. I also think that math teaches you logical thinking that will help you in any career.

- You also need to learn good reading comprehension in high school. All the technician’s paint and bodywork must be done to the manufacture’s specifications. It is important that you can read and understand these manufacturer’s instructions and manuals.

- If you are in high school and think you have an interest in auto body painting and repair and if you live near a technical college you normally can get high school credit for taking classes in the afternoon after you finish your core high school classes. This will give you a chance to get a good idea if it is a career you want to pursue before you leave high school.

- When you graduate you can either look for a shop like ours where we have hired some apprentices or you can go to one of the public technical schools that offer these programs in auto body painting and collision repair. If you can find an apprenticeship, it will save you some time and money. But the technical schools have good programs and high placement rates if you do well and have good recommendations from your instructors. Keep in mind that even if you graduate from a technical school you will have to pay your dues. Collision repairs are expensive and you will be working under supervision until you gain experience. You will also want to take factory training to gain certification, which will allow you earn more.

- There used to be the opportunity in this trade to go out and build you own business. Because of the expense of the new equipment, this is going to become more and more difficult in the future in my opinion. The career path for most people is going to be working with the larger dealerships and advancing within that organization.

Summary

Auto body repair is a good trade for those of you with mechanical ability and some artistic talent. It challenges you to diagnose how to repair the damage and lets you use your artistic skills painting the car and making cosmetic repairs. You will use your mechanical skills when you deal with structural damage and do things like straighten frames and fit body panels. You will earn more money as your gain your certifications. There is also the opportunity to earn more if you are able to move up to a management or supervisory position as you gain experience. Plus shops like ours that have high standards and take pride in what we do are good places to work. This has been a good trade for me that has allowed me to raise a family with six children and can be a good career for you as well if you have the skills and the strong work ethic you need to succeed as a collision technician.

US Bureau of Labor Statistics

Auto body repair technicians received a mean $19.99 per hour or $41,570 per year as of May 2011, according to the Bureau of Labor Statistics. The top 10% of auto body repair techs earn more than $31.27 per hour or $65,030 per year, while the lowest 10% make just $10.83 per hour or $22,530 per year. Technicians examine damage, prepare cost estimates and plan the work. They remove defective parts, hammer out or patch dents and other minor body damage, weld or attach replacement parts, sand and buff surfaces, and apply new paint and other coatings to restored areas.

Of the 131,040 auto body repair techs that worked in the country in 2011, more than 70 percent were employed by automotive repair and maintenance shops. Pay here ran a mean of $19.64 per hour or $40,850 per year. Car dealers provided more than 20 percent of the jobs with mean salaries of $21.04 per hour or $43,760 per year. Wholesalers of motor vehicles and their parts rounded out the top three, averaging $18.96 per hour or $39,440 per year. Pay scales were highest for luxury car dealers where manufacture’s certification and training was required. Manager also made more than technicians.

Employment of automotive body repairers is projected to grow 13 percent from 2012 to 2022, about as fast as the average for all occupations.